From Geo Metro to Performance Car | Veloster N Short Shift Trans Adapter

Posted by Steve on 6th Dec 2019

On a performance-oriented car such as the Veloster N the shifter should feel just as good as the car performs. The Veloster N is a wonderful performer in stock form especially when equipped with the Performance Pack. That performance pack adds an electronic LSD, Valved Exhaust, as well as larger brakes and,19” wheels. Around a track, the Veloster N is an absolute blast, but we noticed a bit of an issue with the shifter in stock form. Throws were on the longer side and the shifter lacked confidence. We found ourselves looking at the gear indicator far too often because there wasn’t enough feedback in the shifter to tell exactly which gear we were in.

Our

engineering team started by looking at each component individually. The shift

lever, shift knob, transmission selector arm, and all of the bushings were

closely analyzed to find room for improvement. We certainly found places that

we can dramatically improve the shifter feel.

We started with shortening up the throws. There are 2 ways that we can do this, and both have to do with the geometry of the shifter cables. On FWD manual cars you generally have 2 shift cables controlling the gear selection. How these cables are attached to the shift lever and selector arm dictates how your shifter throw will be. If the cables are attached far away from the fulcrum point, the throws will be much longer than if they were closer. Bringing the cables closer to the fulcrum means more effort to move the lever. Our engineers set out to find the perfect middle ground; firming up the shifts without adding excessive force to the mix.

Which leads us here, we set out to develop a piece that bolts directly to the transmission arm. Our goal is to bring the cable attachment point to the perfect location shortening shifts without adding excessive force.

The first

step in this journey is to remove the stock selector arm and utilize our Romer

CMM (coordinate measuring machine) and reverse engineer the stock selector arm.

This allows us to input the exact position of the fulcrum, arm, and any

mounting points. We then take all these measurements and import them into our

CAD software.

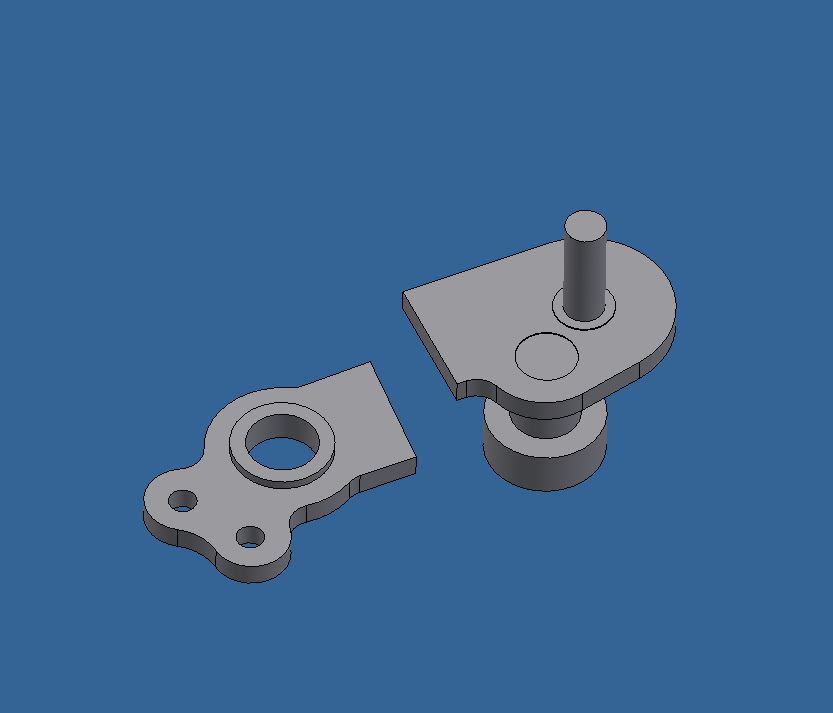

Once

importing them into our CAD software we design a piece that slides over the

stock arm and allows the cable to be attached much closer to the fulcrum. In

the case of the Veloster N we also wanted to bring the lever a bit closer to

the steering wheel. We felt as if the lever was just a bit far of a reach from

an aggressive driving position, remedied nicely with just a touch of geometry.

The less time spent with one hand on the steering wheel, the better.

Once we

finalize our design we 3D print a prototype for fitment purposes. After a few

hours of printing the transmission adapter is ready to be installed on the car

for final clearance checks. Once everything checks out, we send the file to our

milling department so they can make a few prototypes from billet steel.

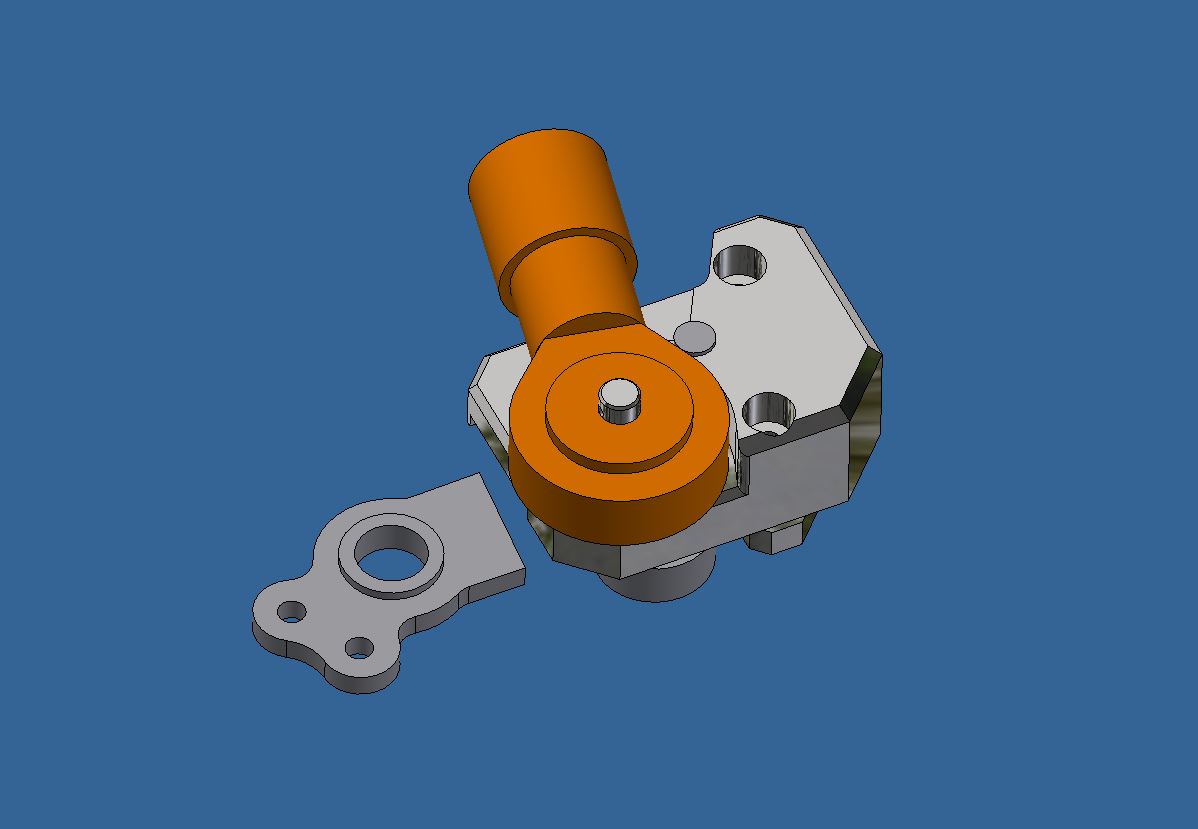

Once they

come off the mill they get sent over to our assembly department. Here they will

press in the shifter pin, as well as pair together any necessary hardware. Then

they hand it back to our engineers, we install it on the car and head out on

the road. We put a number of miles on the car with the trans adapter installed

ensuring there are no issues. There is no better way to test a product than to

bring it into a real-world situation. Once we are satisfied with the final product,

we release it to the public.

This transmission adapter really makes the Veloster’s shifter feel like it should from the factory: short, crisp, and much more engaging. It feels blissful rowing the gears now, after all there is nothing more satisfying than a nice quick gear change in a manual car. Especially that high RPM 2-3 change accompanied by the noise this car is so well known for, those pops.

These adapters are on our website now!